Understanding Cone 6 NCECA Presentation 2018 Sue McLeod Ceramics

Generate cone temperature chart and see the conversion between kiln cones in Fahrenheit and Celsius based on selected heat rate increase. Hourly Heat Change: -Select - 27°F (15°C) - slow 108°F (60°C) - medium 270°F (150°C) - fast

Cone Temperature Conversion Chart Temperature conversion chart, Temperature chart, Conversion

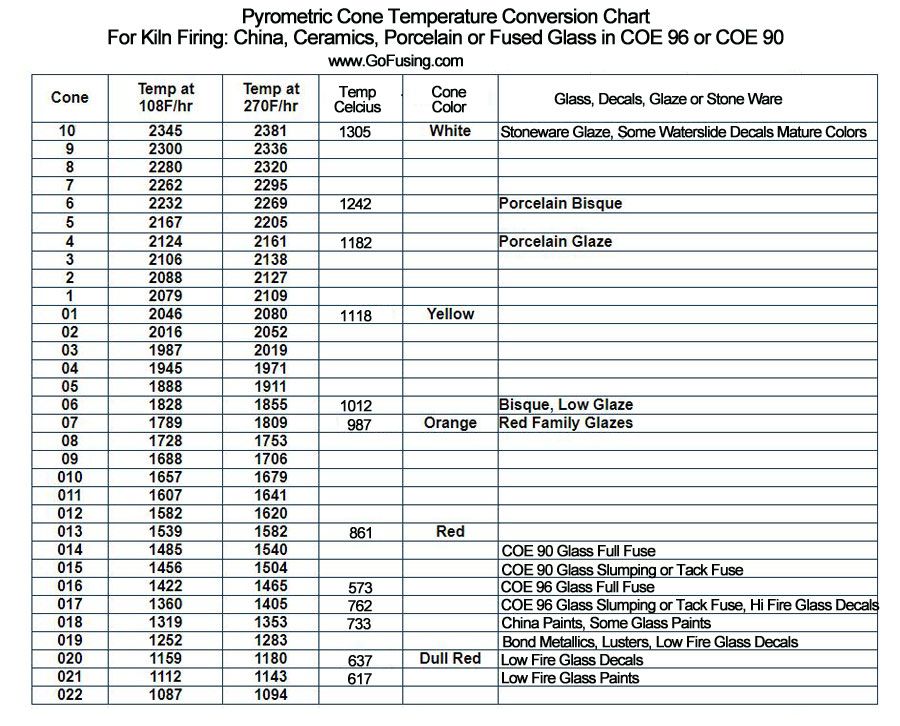

NUMBER: 022 TO 011 - Used in firing of overglaze decorations, lusters, enamels, and decals and for glass fusing, slumping, and decorating. The temperature equivalent range is approximately 1050 - 1550F (560 to 850C). NUMBER: 010 TO 3 - Made as a regular series (red, iron-containing cones) and as an Iron Free series for use in reducing atmospheres.

How to Convert a Cone to Fahrenheit or Celsius Temperatures

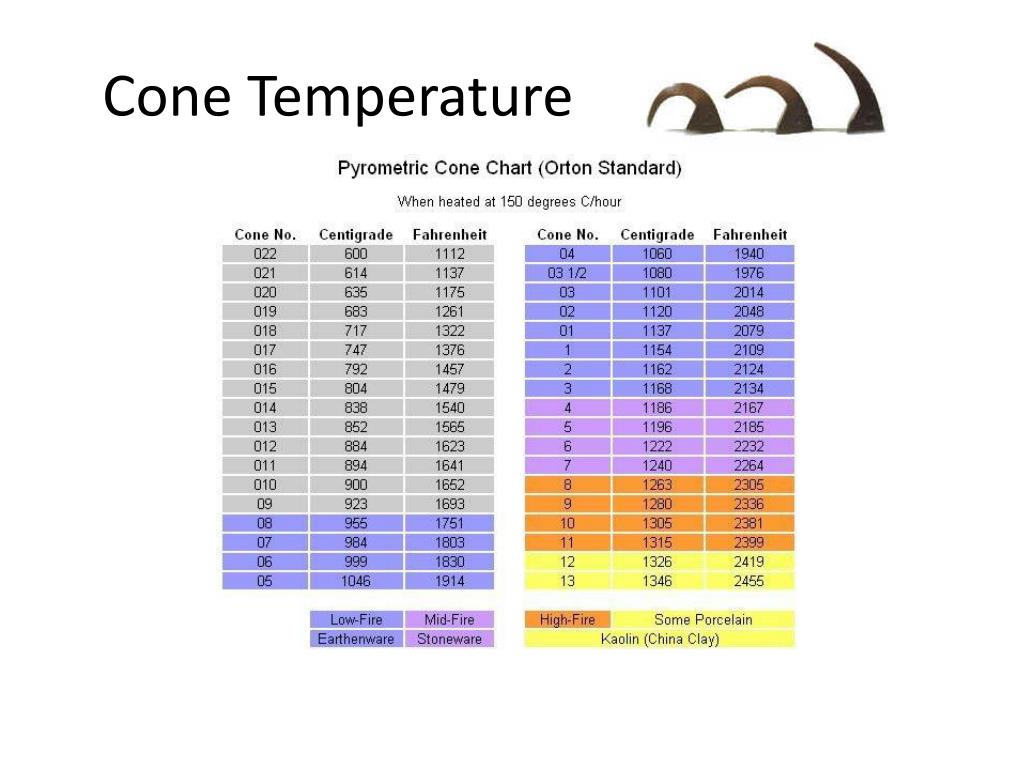

Cone 6 is about 400 degrees hotter than cone 06! As you can see from the pyrometric chart (above), the "0" serves as a negative sign.. If your clay's recommended firing temperature is cone 06-04, then you should use low-fire glazes. These may say on the label something like "apply to shelf cone 04 bisque and fire to cone 06-05".

Pyrometric Cone Chart for Kiln Firing

Mid-Range Pottery is fired at intermediate temperatures, typically between 2,100°F and 2,300°F Cone 5-6 (1,150°C to 1,260°C). It is frequently used with stoneware clay bodies, which are less porous and more durable than earthenware clay bodies. Because of its adaptability and consistency, mid-range firing is the choice of many contemporary.

cone chart Temperature chart, Cones, Cone

cone 06-04 and cone 4-6. Note: the word cone is often replaced with this symbol Overglaze enamels. Lusters (metallics and irridescents) All cones mature with time and temperature All temperature equivalents on this chart are based on a 270° F (150° C) per hour rate climb using the large cone. Rates of climb change per firing as do temperature

What is a Cone? A Guide to Pyrometric Cones and Kilns Pottery kiln, Kiln, Ceramics ideas pottery

What does cone 6 kiln fire to? How many degrees is cone 04 or cone 10? Calculator converts cone to its firing temperature in fahrenheit or celsius, and based on the heating rate of the kiln.. Calculate kiln cone temperature for cone 022 to cone 10, based on the kiln's heating rate. Cone Size: Temperature Unit: Use the Cone Comparison.

Understanding Cone 6 Sue McLeod Ceramics

A cone is how we gauge the temperature that we are firing to. There are many different cone levels which all result in different temperatures that your Kiln will fire to. To start though lets mainly just focus on cone <06 and <6. There are different holds and firing schedules that you can set your kiln to, which in results into different per.

Kiln, Cone, Temperatures

Cone 06 fires at a much lower temperature compared to cone 6, and the same applies to cone 05 as well. For cone 05, the firing temperature is 1870 degrees Fahrenheit, while the firing temperature for cone 06 is 1798 degrees Fahrenheit. In the pottery world, the placement of "0" ahead of a number represents "minus.".

Potclays, Manufacturer of clays, glazes and kilns Standard Cone 06

Find Information About Pyrometric Cones and temperature Conversion Chart at Clay-King.com, See Ware and Glaze Types. | More. Cone Temperature Conversion Chart: Cone: Temp at 108F/hr: Temp at 270F/hr: Kiln Color: Ware and Glaze Types: 10* 2345: 2381: White: Stoneware Glaze, *Some Decals fire to Cone 10: 9: 2300: 2336: 8:

cone and temp color orton pyrometric temperature chart Ceramics, Ceramic glaze recipes

The average firing temperature for high-fire stoneware is 2381℉ (1305℃). However, anywhere from 2305℉ to 2336℉ (1263℃ to 1326℃) may be appropriate depending on the specific clay used and desired effect. Cone range. Between the range of Cone 8 and Cone 12, high-fire stoneware will mature. Cone 10 is the average for this clay body.

What is Cone? Cone, Temperature chart, Chart

Note that cone 01 and cone 1 are not the same. On the cone scale, the 0 in front of a number is thought of as a negative sign. So cone 6 is a higher temperature than cone 5. However, cone 06 is a lower temperature than cone 05. What cone is bisque firing? Bisque firing is normally performed between cone 08 and cone 05.

Pyrometric Cone Temperature Chart Temperature chart, Temperature conversion chart, Cone

Cone 5 Also called "middle temperature" by potters, cone 5 (~2160F/1180C) refers to the low end of the temperature range at which most hobby and pottery stonewares and porcelains are fired. Recipes: G2934Y - Cone 6 Magnesia Matte Low LOI Version The same chemistry as the widely used G2934 but the MgO is sourced from a frit and talc instead of.

8 Ceramic Cone Temperature Chart 2k24

I fire my cone 6 glazes to cone 7 using a programmable controller with the following heating and cooling cycle: 1st segment - 50°F/hour to 220°F. 2nd segment - 250°F/hour to 2167°F. 3rd segment - 150°F/hour to 1500°F. I have found that this provides a better melt and allows a good mingling of the many layers of glaze.

Understanding Cone 6 NCECA presentation 2018 Sue McLeod Ceramics

Orton Pyrometric Cone Chart in Fahrenheit and Celsius. November 2, 2022 Matt M-H. Melted large Orton pyrometric cones 5, 6 and 7. Cone pack is pictured after being removed from the kiln. Pyrometric cones are designed to melt at certain temperatures in a kiln. They measure "heat work" during a firing, or time plus temperature.

PPT Stages of Clay PowerPoint Presentation, free download ID2278112

Cone 6 temperatures. Kiln firing at cone 6 temps is considered a "mid" firing range. The "mid" firing range is the most common range for potters to do a final glaze firing. A potter's finished pieces will be fired in this range. Kiln cone 6 ranges in Fahrenheit.

Cone 6 Glaze Recipes Electric Kilns

This temperature range is slightly lower than cone 6 and is considered a mid-range firing temperature for ceramics. Advantages of Cone 5 Firing. Lower Energy Consumption: Since cone 5 firing occurs at a slightly lower temperature than cone 6, it generally consumes less energy, potentially resulting in cost savings for the artist or studio.